The smart Trick of 24hr Media That Nobody is Discussing

Table of ContentsNot known Incorrect Statements About 24hr Media Getting My 24hr Media To WorkThe Buzz on 24hr MediaThe Of 24hr MediaNot known Incorrect Statements About 24hr Media

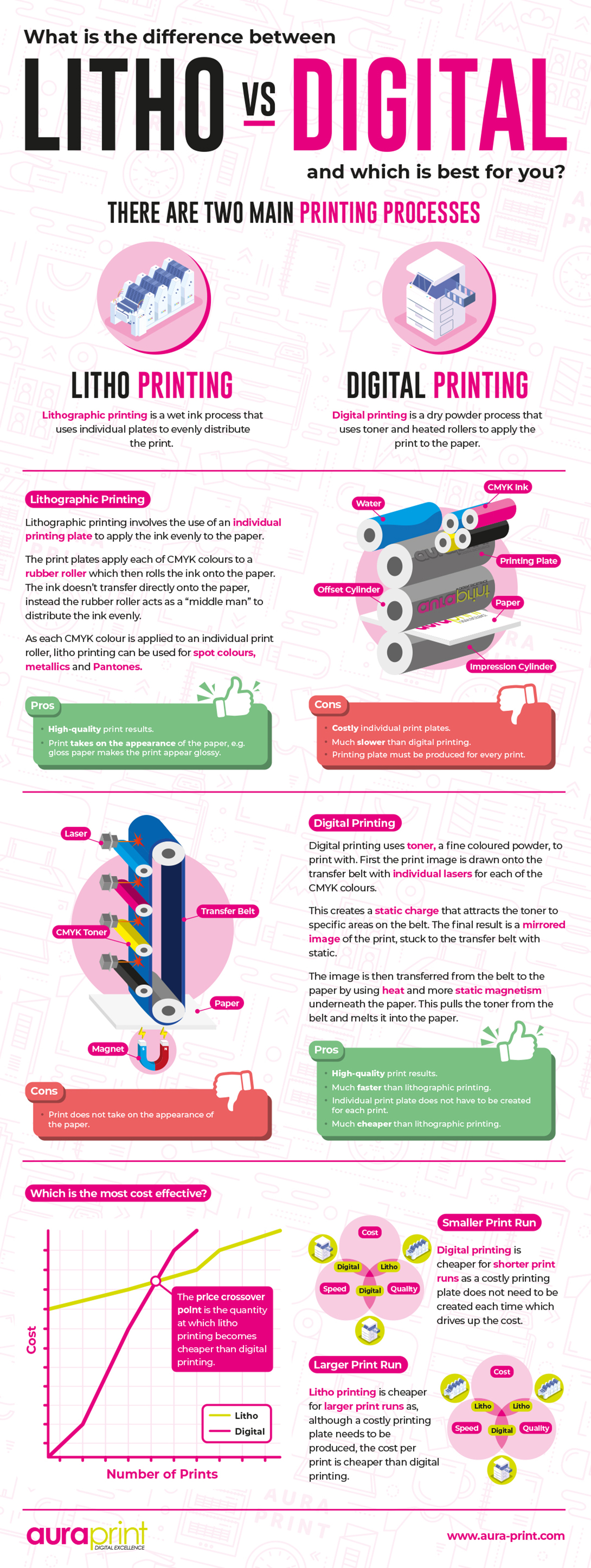

Offset, gravure printing and flexography are one of the most typical types of standard printing in the product packaging area and each involves moving the picture from a plate to the surface. To do this, first the plate requires to be produced, and it is the development of these plates that require time, and set you back money.According to PMMI, electronic printing enables brands and producers to react swiftly to client needs while enhancing the supply chain, minimizing warehousing cost and waste, and delighting in faster time to market. That all sounds wonderful, yet exactly how does this technology do all that? The significant differentiator of these innovations is that there are no set-up costs and no plates with digital printing.

According to Wikipedia, the best distinction between electronic printing and conventional techniques such as lithography, flexography, gravure, or letterpress is that there is no requirement to replace printing plates in digital printing, whereas in these analog printing approaches the plates are repeatedly replaced. This leads to quicker turnaround time and decreases price when utilizing electronic printing.

(https://www.indiegogo.com/individuals/38421504)

Quick production means obtaining your product to market quicker. It likewise means it's less complicated and faster to make changes later, when you alter a recipe, include a SKU, or produce seasonal product packaging. Digital printing is highly adaptable, so it's easy to make adjustments to the package layout rapidly. All of it goes back to the plates.

Some Ideas on 24hr Media You Need To Know

A lot more inventory can imply even more waste down the roadway. With conventional printing techniques, short-run printing is just not possible. Since a terrific layout can make or damage your item, electronic printing consistently produces high-grade, clear and colorful graphics each time. Digital printing on adaptable bags adds the brilliant, lively, and specific graphics that almost beckon consumers to connect and touch them.

Packing ... Are you acquainted with the advantages of digital printing? Continue reading to recognize when electronic printing can be the very best possible remedy for your organization. Do you recognize why electronic printing has ended up being the favorite choice of some businesses? Both countered and electronic printing have their location in the printing market.

In this short article, we will certainly go over the advantages of electronic printing to assist you better recognize if digital printing is simply what you need. Merely put - electronic printing prints material straight onto the paper.

How 24hr Media can Save You Time, Stress, and Money.

As digital printing regularly advances, it provides a lot more opportunities and higher output high quality every day. Sometimes, the print top quality can be as high as to balance out printing. As years pass, electronic print is becoming a lot more easily accessible, with improved speed and top quality. This is simply the factor printing business are including electronic printing to their offer.

For countered printing, if any type of error goes undetected prior to developing home plates, there will be a high expense of producing a new one. However, with digital printing, this is not the situation. Everyone always hopes there will be no mistakes, knowing the price of remedying them if they happen is constantly an excellent idea.

This means every solitary piece will certainly look the exact same, so the possibility you will need to discard any of them due to inconsistencies is reduced. Also, since a proofing example is published on the exact same device as the item itself, color proofing is really precise. Any issues with shade will show up on the proof, and therefore it will certainly be possible to transform it before publishing the entire run.

The Ultimate Guide To 24hr Media

Digital printing, on the other hand, calls for marginal setup. This is terrific when you are in a hurry to get your printed materials.

This means even more demands for digital on-demand print manufacturing. Every customer appreciates a customized message. Among the advantages of digital printing is that personalizing your marketing products could not be simpler. Cost-effective, smaller sized batches enable businesses to tailor each order. Have a back-to-school sale? Make a leaflet to target moms and dads and another one to target the students.

Digital printing is the perfect selection for variable data printing, like personalized codes and addresses on straight mail. With digital printing, it is less troublesome to make last-minute modifications to your layout.

How 24hr Media can Save You Time, Stress, and Money.

There is additionally no demand to clean up the plates after printing. The advantages of digital printing include that there is no waste from added or leftover ink, paper, or chemicals because only what's required obtains printed. - for very brief runs, electronic printing is the way to go, certainly.

Gone are the days of intricate arrangements and long turn-around times - digital printing has actually changed the print industry. The printing globe has come a long method considering that the days of Gutenberg's printing press. The brand-new normal is structured procedures and affordable services for printing onto practically anything you can think about.

Comments on “Excitement About 24hr Media”